CIENCIAS

NUCLEARES

Radiation induced graft copolymerization of acrylamide onto poly (3-hydroxybutyrate)

Copolimerización por injerto radioinducido de acrilamida en el poli (3-hidroxibutirato)

Maykel González

Torres1, Manuel Rapado Paneque2, Mayte Paredes Zaldívar2, Sonia Altanés

Valentín2, Gisela Barrera González2

1Instituto de Ciencia y Tecnología de Materiales (IMRE), Universidad de La Habana, Cuba

2Centro de Aplicaciones Tecnológicas y Desarrollo Nuclear (CEADEN)

Calle 30 No 502 e/ 5ta Ave. y 7ma, Playa, Ciudad de La Habana, Cuba

ABSTRACT

The graft copolymer poly (3-hydroxybutyrate)-g- polyacrylamide [P (HB-g-AAm)] was synthesized by radiation induced graft copolymerization of acrylamide onto poly (3-hydroxybutyrate). The study was conducted by the simultaneous irradiation method. The structure of [P (HB-g-AAm)] was identified by Fourier Transform Infrared (FTIR) spectroscopy. Thermal behavior of the graft copolymer was also studied by Thermal Gravimetric Analysis (TGA) and Differential Scanning Calorimetry (DSC). According to the results, FTIR studies showed new signals (stretching-N-H) as an important evidence of grafting. The grafting degree, determined by ATG, was 10% and changes in thermodynamic parameter obtained from the DSC were detected. Such changes show a decrease in crystallinity and an increase in the glass transition temperature. These results demonstrate that the gamma radiation-induced graft copolymerization reaction of acrylamide onto PHB was successively achieved.

RESUMEN

En el trabajo se realizó la síntesis del copolímero por injerto poli (3-hidroxibutirato)-g- poliacrilamida [P (HB-g-AAm)] por copolimerización de injerto radioinducido del monómero acrilamida en el PHB. El estudio se llevó a cabo por el método de la irradiación simultánea. La estructura del copolímero se identificó por espectroscopía Infrarrojo por Transformada de Fourier (FTIR). Además, se realizó el estudio térmico del compuesto obtenido por análisis termogravimétrico (TGA) y calorimetría diferencial de barrido (DSC). De los resultados se encontraron señales (vibraciones de valencia -N-H) por FTIR que constituyen una importante evidencia de la reacción de injerto. El grado de injerto determinado por ATG fue de 10% y se detectaron cambios en los parámetros termodinámicos estudiados por DSC, que muestran una disminución de la cristalinidad y un aumento de la temperatura de transición vítrea. Los resultados demostraron la formación del copolímero por injerto inducido por radiaciones gamma.

Key words: acrylamide, graft polymers, irradiation procedures, fourier transform spectrometers, thermal gravimetric analysis, copolymers, radiation doses, gamma radiation

INTRODUCCIÓN

Poly (3-hydroxybutyrate)

(PHB) has received considerable attention in the last decade as biodegradable

and biocompatible biomaterial. PHB is a thermoplastic material with physical

properties similar to polypropylene (PP) [1]. Its various properties make it

suitable for a variety of applications in the field of medicine [2]. However,

the PHB homopolymer main drawbacks are its relatively hydrophobicity, brittleness

and thermal instability. It is known that these problems can be solved by the

incorporation of new molecules to the PHB backbone by graft copolymerization.

On the other hand, polyacrylamide has shown to be «biocompatible»,

although some controversy exists with respect to its blood biocompatibility

[3, 4]. The covalent grafting of hydrophilic polymers onto hydrophobic substrates

is widespread. Graft polymerization is a well-known method to modify the chemical

properties of polymers for specific application [5-9].

Lee et al studied graft copolymerization of acrylamide onto poly (hydroxybutyrate-co-hydroxyvalerate)

film to test the application of the grafted film on permselectivity [10].

Hydrophilic monomers, including methyl methacrylate (MMA), 2-hydroxyethyl methacrylate

(HEMA) and acrylic acid (AAc) have been grafted onto PHB and its copolymers

P (HB-co-HV) through radiation induced graft copolymerization [11-13]. Other

monomer such as styrene (St) was grafted by using the simultaneous radiation

and pre-irradiation techniques from a  g-ray source [14]. In addition Hu et al reported the graft copolymerization

of isoprene (Ip) obtained by directly irradiating the polymer immersed in isoprene

solution [15].

g-ray source [14]. In addition Hu et al reported the graft copolymerization

of isoprene (Ip) obtained by directly irradiating the polymer immersed in isoprene

solution [15].

In previous paper the radiation induced graft copolymerization of vinyl acetate onto PHB was performed [16, 17]. The study reported here is concerned with the radiation induced graft copolymerization of typical acrylamide onto PHB by the simultaneous irradiation method. Simultaneous irradiation is the simplest irradiation technique for preparation of graft copolymers. In this method a polymer backbone is irradiated in the presence of a monomer available in different forms: vapor, liquid or in bulk solution. The purpose of grafting AAm onto PHB is to improve its hydrophilic characteristics. The product obtained in this work has not been reported before by any authors. It was characterized by means of several techniques to verify the graft copolymer synthesis.

MATERIALS AND METHODS

Materials

Poly (3-hydroxybutyrate)

(PHB) was available from the Institute of Research and Technology, Biotechnology

Section (Brazil). It was purified by precipitation in ethanol from chloroform

solutions. The molecular weights were determined by GPC at room temperature

with a PUMP 64 HPLC (KNAUER), equipped with a series of five columns PL-Gel

and KNAUER differential refractometer. Tetrahydrofuran (THF) solvent was used

at 1 mL/min flow rate, and it was also used injection volumes of 20 µL.

Polystyrene standards with low polydispersity were used to generate a calibration

curve. The results were:  n

= 27000,

n

= 27000,  w

= 60000;

w

= 60000;  z

= 98000; Polydispersity = 2.22.

z

= 98000; Polydispersity = 2.22.

Acrylamide was available from Merck (Ge) and was previously purified by recrystallization

method.

Graft copolymer synthesis (P (HB-g-AAm))

The irradiation

experiment was carried out in glass sealed vacuum ampoules at room temperature.

PHB (200 mg) was immersed in AAm (1g) and 1 mL of the solvent (acetone). The

mixture was subjected to

-ray

at a dose rate of 1. 62 kGy/h and a dose of 10 kGy. The grafted PHB so obtained

was extracted in a Soxhlet apparatus with ethanol and acetone for 72 h, to remove

any acrylamide monomer and PAAm homopolymer obtained as collateral products.

The copolymer P (HB-g-AAm) was dried under vacuum, at 40 C, to constant weight.

-ray

at a dose rate of 1. 62 kGy/h and a dose of 10 kGy. The grafted PHB so obtained

was extracted in a Soxhlet apparatus with ethanol and acetone for 72 h, to remove

any acrylamide monomer and PAAm homopolymer obtained as collateral products.

The copolymer P (HB-g-AAm) was dried under vacuum, at 40 C, to constant weight.

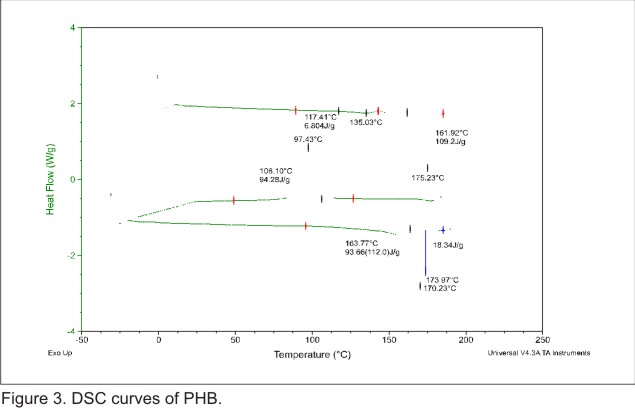

The following equation to determine the degree of grafting (W (%)) in the graft copolymerization reactions is often used:

Where  (g) is the initial weight of the original base backbone polymer and mg (g) is

the graft copolymer weight after grafting. This variable is an alternative to

elucidate the graft % by means of the mass increase.

(g) is the initial weight of the original base backbone polymer and mg (g) is

the graft copolymer weight after grafting. This variable is an alternative to

elucidate the graft % by means of the mass increase.

Characterization

Thermal analysis

The study of the

graft copolymer (P (HB-g-AAm)) obtained by radiation induced graft copolymerization

was conducted by Thermal Gravimetric Analyses (TGA) in a Q500 TA Instruments,

at a heating rate of 10°C/min at nitrogen atmosphere. The samples weight

was of 5-15 mg and the temperature range of 50- 600°C at atmosphere.

Thermal properties

were also investigated using Differential Scanning Calorimetry (DSC), on a TA

Instrument 2920 under nitrogen atmosphere. In the DSC experiments, at first,

at the heating rate of 10°C/min, the sample was heated from -30 to 180°C

(first heating scan), and keep for few minutes at 180o C. After eliminating

the thermal history, the sample was cooled to -30°C (-10°C/min) and

finally the sample was heated from -30 to 180°C at the heating rate of 10°C/min

(second heating scan). The enthalpy and the transition temperatures were determined

from exothermic and endothermic peaks in the second run.

FTIR studies

Fourier Transform Infrared (FTIR) transmittance spectra (520 scans, 4 cm- resolution, wave number range 400-4000 cm-), were recorded using a Bruker Vertex 70 FTIR Spectrometer. All spectra were baseline corrected. The sample was prepared in KBr pellets. The study was performed with the diffuse reflectance accessory (EasiDiff).

RESULTS AND DISCUSSION

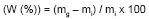

Figure 1 show the

radiation induced graft copolymerization reaction of acrylamide onto PHB. The

simultaneous irradiation technique with  gamma-ray was used. The dose rate was 1. 62 kGy/h and the dose was 10 kGy at

room temperature. The selection of the source, dose rate and dose used are based

on the results obtained in the radiation induced graft copolymerization of other

monomers onto PHB synthesized by the authors. For instance the P (HB-g-VAc).

These parameters have also been used in the syntheses of the graft copolymers

found in the literature [11-15]. It is important to mention here that generally,

higher irradiation doses lead to higher degrees of grafting. This is due to

the enhancement of free radical formation. But the graft copolymer is always

obtained at doses over 5 KGy. We have chosen 10 KGy because it was verified

experimentally that this value is appropriate to be used.

gamma-ray was used. The dose rate was 1. 62 kGy/h and the dose was 10 kGy at

room temperature. The selection of the source, dose rate and dose used are based

on the results obtained in the radiation induced graft copolymerization of other

monomers onto PHB synthesized by the authors. For instance the P (HB-g-VAc).

These parameters have also been used in the syntheses of the graft copolymers

found in the literature [11-15]. It is important to mention here that generally,

higher irradiation doses lead to higher degrees of grafting. This is due to

the enhancement of free radical formation. But the graft copolymer is always

obtained at doses over 5 KGy. We have chosen 10 KGy because it was verified

experimentally that this value is appropriate to be used.

The structure shown in the figure suggested that the graft occurs through the tertiary PHB carbon. This can be considered because of previous studies [18]. Sevilla et al reported that the tertiary radical formed by the exposition of PHB to gamma-radiation would be favored with respect to the rest possible radicals formed. In our previous studies, the P (HB-g-VAc) was reported [19]. Spectroscopic studies showed that quaternary substituted carbons were obtained. This result is in agreement with the propose structure given for P (HB-g-AAm). On the other hand, Grushevskaya et al reported that acetone is the more convenient solvent to be used in the radiation induced graft copolymerization of acrylamide onto PE. From this finding acetone was used as diluent in this work [20].

FTIR

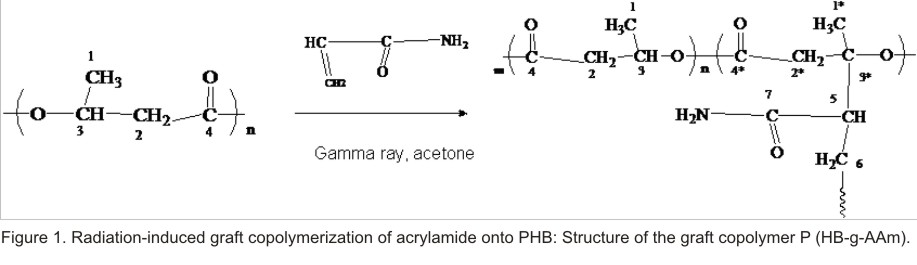

FTIR studies were

performed in order to confirm the syntheses of a graft copolymer. Evidence of

grafting was obtained by using this technique. Figure 2 shows the transmittance

mode FTIR spectra of pure PHB and P (HB-g-AAm). From the IR spectra, it was

obvious that PHB showed the bands at 1185, 1228 and 1279  characteristic of

characteristic of  (C-O-C) and the band at 1382

(C-O-C) and the band at 1382  characteristic of

characteristic of  (

( ).

In the ester carbonyl region, it can be considered the band of the C=O stretching

(1729

).

In the ester carbonyl region, it can be considered the band of the C=O stretching

(1729  ). All this

mentioned signals are common for both materials. However in the graft copolymer,

apart of the previous peaks, four additional peaks were present. Two peaks at

3300 cm- (broad peak) and 3182 cm- were for the

). All this

mentioned signals are common for both materials. However in the graft copolymer,

apart of the previous peaks, four additional peaks were present. Two peaks at

3300 cm- (broad peak) and 3182 cm- were for the  groups, corresponding to symmetrical and antisymmetrical stretching -N-H bonds.

The peak position at 1676 cm- is probably caused by the amide carbonyl group

and the 1608 cm- peak represents the adsorption of

groups, corresponding to symmetrical and antisymmetrical stretching -N-H bonds.

The peak position at 1676 cm- is probably caused by the amide carbonyl group

and the 1608 cm- peak represents the adsorption of  (NH). The absorption frequency of carbonyl stretching vibrating of the amide

group is well separated from that of the ester group. The new peaks observed

are a strong evidence of grafting and clearly indicate the formation of a graft

copolymer.

(NH). The absorption frequency of carbonyl stretching vibrating of the amide

group is well separated from that of the ester group. The new peaks observed

are a strong evidence of grafting and clearly indicate the formation of a graft

copolymer.

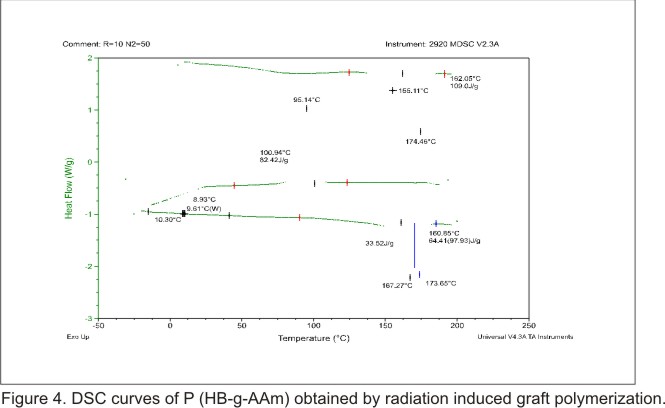

Differential Scanning Calorimetry (DSC) investigation

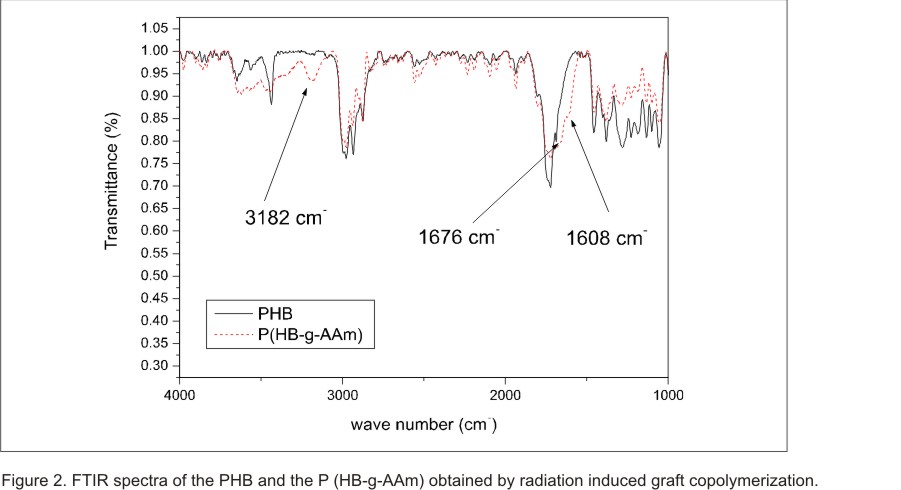

Thermal properties

of the grafted PHB (figure 3) and the P (HB-g-AAm) were investigated by DSC

with the purpose to demonstrate the graft copolymer formation by means of the

differences observed among both materials. Figure 4 is the thermogram of graft

copolymer. In the DSC thermogram of the first scan was observed the fist anomaly

among both materials. The graft copolymer showed bimodal peaks at 175.11°C

and 174.46°C with respect to PHB endothermic melting (175.23°C). In

addition in the DSC of the second scan was observed that the crystallization

temperature changed its value from 97.4°C (PHB) to 95.4°C (P (HB-g-AAm))

and the enthalpies of crystallization (  )

changed its value from 94.28 J/g (PHB) to 82.42 J/g (P (HB-g-AAm)). What is

more, in the DSC thermogram of the third scan was also observed anomalies. The

thermogram of the product showed bimodal peaks in the melting region. Surprisingly

the melting point (

)

changed its value from 94.28 J/g (PHB) to 82.42 J/g (P (HB-g-AAm)). What is

more, in the DSC thermogram of the third scan was also observed anomalies. The

thermogram of the product showed bimodal peaks in the melting region. Surprisingly

the melting point ( )

of the graft copolymer was three degrees up and down the value of the

)

of the graft copolymer was three degrees up and down the value of the  given for PHB. Consequently, the enthalpies of melting (

given for PHB. Consequently, the enthalpies of melting ( )

of the plain PHB and the graft copolymer differed in about 15 units (J/g). The

decrease of the

)

of the plain PHB and the graft copolymer differed in about 15 units (J/g). The

decrease of the  for the graft copolymer indicated that the cristallinity decreased after the

introduction of AAm chains onto the PHB backbone by radiation induced graft

copolymerization. It is of interest to mention here that the

for the graft copolymer indicated that the cristallinity decreased after the

introduction of AAm chains onto the PHB backbone by radiation induced graft

copolymerization. It is of interest to mention here that the  of plain PHB changed from -2°C to 9.61°C in the graft copolymer, laying

between those of the two homopolymers. This result is consistent with the fact

that is natural that the introduction of AAm chains onto PHB increases the glass

transition temperature.

of plain PHB changed from -2°C to 9.61°C in the graft copolymer, laying

between those of the two homopolymers. This result is consistent with the fact

that is natural that the introduction of AAm chains onto PHB increases the glass

transition temperature.

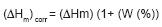

Table lists the

thermodynamic parameters obtained from the DSC thermogram of the experiment

sample. It was summarized the melting point ( ),

the enthalpies of melting (

),

the enthalpies of melting ( ),

the enthalpies of melting

),

the enthalpies of melting  corrected by the weigh fraction of the polymer that conform the graft copolymer,

calculated according to the following equation:

corrected by the weigh fraction of the polymer that conform the graft copolymer,

calculated according to the following equation:

the crystallization

temperature ( )

and the enthalpies of crystallization (

)

and the enthalpies of crystallization ( ).

From the results obtained by the DSC experiments a strong evidence of grafting

is given.

).

From the results obtained by the DSC experiments a strong evidence of grafting

is given.

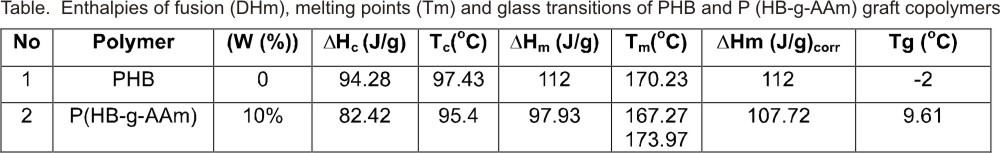

Thermogravimetric analysis (TGA)

Figure 5 illustrates

TGA thermogram of the graft copolymer P (HB-g-AAm). The TGA was conducted to

show the difference in the thermal behavior of the obtained product with respect

to the base polymer (PHB) and the grafting degree calculus. The TG curve of

PHB grafted with AAm shows two steps in its smooth weight loss curve because

the decomposition temperature of PHB and AAm are not the same. The first step

represents the plain PHB material and the second step represents the grafted

PAAm. In addition, the DTGA shows two rates of weight loss (dW/dt) peaks defining

the temperature of each step. The first step at 395°C belongs to PHB characteristic

temperature. The others step at 395°C correspond to PAAm decomposition.

From figure 5 can be seen that the PHB composition in the graft copolymer can

be calculated by dividing the weight loss of the first step to the total weight

loss. This result indicates that the copolymer grafting degree (W (%)) is 10%

(This percentage represent the quantities in mass of PAAm grafted onto PHB with

respect to the total mass of the sample) (see table).

CONCLUSIONS

The radiation induced graft copolymerization reaction of AAm onto PHB has been studied by the simultaneous irradiation method. The results obtained can be summarized as follows:

1- In spite of

the PHB inactive structure, AAm can be grafted onto PHB by directly irradiating

PHB and AAm immersed in acetone solution, using a

-ray

source.

-ray

source.

2- The synthesized material was characterized by means of several techniques

such as FTIR, ATG and DSC

3- FTIR studies showed new signals that strongly confirm the synthesis of P(HB-g-AAm),

such as the peaks at 3300 cm- and 3182 cm- assigned for the  groups, corresponding to symmetrical and antisymmetrical stretching -N-H bonds.

In addition, the absorption frequency of carbonyl stretching vibrating of the

amide group is well separated from that of the ester group.

groups, corresponding to symmetrical and antisymmetrical stretching -N-H bonds.

In addition, the absorption frequency of carbonyl stretching vibrating of the

amide group is well separated from that of the ester group.

4- TGA results showed that graft degree (W (%)) in the graft copolymer is about

10% calculated by dividing the weight loss of the second step to the total weight

loss of the sample.

5- From DSC results, the melting enthalpy ( )

slightly decreased. The decrease of the

)

slightly decreased. The decrease of the  for the graft copolymer indicated that the cristallinity decreased after the

introduction of AAm chains onto the PHB backbone by radiation induced graft

copolymerization. Some experiments displayed bimodal peaks during the DSC in

the third scan, which could be caused by recrystallization processes. Consequently,

the glass transition temperature increased its value as a result of the grafting.

for the graft copolymer indicated that the cristallinity decreased after the

introduction of AAm chains onto the PHB backbone by radiation induced graft

copolymerization. Some experiments displayed bimodal peaks during the DSC in

the third scan, which could be caused by recrystallization processes. Consequently,

the glass transition temperature increased its value as a result of the grafting.

6- These results demonstrate that the radiation induced graft copolymerization

reaction of acrylamide onto PHB was successively achieved.

Acknowledgment

The authors are grateful to: Dr Ramiro Guerrero, Dr Enrique Saldívar, Silvia Solís, Blanca Huerta Guadalupe Mendez and Judith Cabello from CIQA (Centro de Investigación en Química Aplicada, México) for their assistance with TGA and DSC data collection. We would also thank to Dr Judith Percino and Dr V.M Chapela from the Benemérita Universidad Autónoma de Puebla (BUAP), Joaquín Iglesias (Glass technician specialist) from Biomat (UH-Cuba), and Dr Ricardo Aroca from the Windsor University of Canada.

REFERENCES

[1] SUDESH K, ABE H, DOI Y. Syntheses, structure and properties of polyhydroxyalkanoates: biological polyester. Prog. Polym. Sci. 2000; 5: 1503-1555.

[2] ZINN M, WITHOLT B, EGLI T. Occurrence, syntheses and bacterial application of bacterial polyhydroxyalkanoate. Advanced Drug Delivery Reviews 2001; 53: 5–21.

[3] HOFFMAN AS, BUDDY RD. The radiation grafting of acrylamide to polymer substrates in the precence of cupric ion-I. A preliminary study. Radiat. Phys. Chem. 1979; 14: 831-840.

[4] DESSOUKI AM, HEGAZY EA, EL-ASSY NB, EL-BOOHY HA. Radiation-induced graft polymerization of acrylamide: reverse osmosis properties of polyethylene-g-polyacrylamide membrane. Radiat. Phys. Chem. Int. Jnl. Radiat. Applic. Instrum, Part C. 27(6), 1986; 431-436.

[5] GRUSHEVSKAYA LN, ALIYEV RE, KABANOV VY. Radiation induced graft polymerization of acrylamide and acrylic acid onto polyethylene. Int. Jnl. Radiat. Applic. Instrum Part C. 1990; 36 (3): 475-479.

[6] GUPTA B, ANJUM N. Surface Structure of Radiation-Grafted Polyethylene-g-Polyacrylamide Films. J Appl Polym Sci. 2002; 86: 1118–1122.

[7] FAYEK SA, EL SAYED SM, EL-ARNAOUTY MB. Study the effect of gamma irradiation on optical and morphological properties of grafted low density polyethylene. Polymer Testing. 2000; (19): 435–443.

[8] DESSOUKI AM, TALLER NH, EL-BOOHY HA. Radiation-induced graft polymermization of acrylamide onto

poly (tetrafluoroethylene/hexafluoropropylene/vinylidene fluoride) (tfb) films.

Radiat. Phys. Chem. Int. Jnl. Radiat. Applic. Instrum, Part C. 1990; 36 (3): 371-375.

[9] KE Y, WANG Y, REN L, et al. Polymerization of Polyacrylamide on PHBV Films (I). Appl Polym Sci 2007; 104: 4088–4095.

[10] SUP LEE H, YOUN LEE T. Graft polymerization of acrylamide onto poly( hyd ro xyb utyrate- co- hyd ro xyvalerate) films. Polymer. 1997; 38 (17): 4505-4511.

[11] MITOMO H, ENJÔJI T, WATANABE Y, et al. Radiation induced graft polymerization of poly (3-hydroxybutyrate) and its copolymer. Pure Appl. Chem. 1995 ; A32(3): 429-442.

[12] GRØNDAHL L, CHANDLER-TEMPLE A, TRAU M. Polymeric Grafting of Acrylic Acid ontoPoly (3-hydroxybutyrate-co-3-hydroxyvalerate): SurfaceFunctionalization for Tissue Engineering Applications. Biomacromolecules. 2005: 2197-2203.

[13] WADA Y, MITOMO H, et al. Control of biodegradability of poly(3-hydroxybutyric acid) film with grafting acrylic acid and thermal remolding. J Appl Polym Sci. 2006 ; 101: 3856–3861.

[14] BAHARI, K, MITOMO, H, ENJOJI, T, et al. Radiation induced graft polymerization od styrene onto poly (3-hydroxybutyrate) and its copolymer with 3-hydroxyvalerate. Die Angewandte Makromolekulare Chemie. 1997; 250(4352): 31-44.

[15] JIANG T, HU P. Radiation-Induced Graft Polymerization of Isoprene onto Polyhydroxybutyrate. Polymer Journal, 2001; 33(9): 647-653.

[16] GONZÁLEZ M, GALEGO N, ORTIZ DEL TORO P, RAPADO M. Espectroscopia Raman del poli(3-hidroxibutirato), modificado con poliacetato de vinilo por copolimerización radioinducida. Nucleus, 2007 ; (42): 40-44.

[17] WADA Y, SEKO N, NAGASAWA N, TOMADA M, KASUYA K, MITOMO H. Biodegradability of poly (3-hydroxybutyrate) film grafted with vinyl acetate: effect of grafting and saponification Radiation Physics and Chemistry. 2007; (76): 1075-1083.

[18] CARSWELL T, HILL DJT. An electron spin resonance study of the radiation chemistry of poly (3-hydroxybutyrate). Radiat. Phys. Chem. 1995; 45(5): 737-744.

[19] GONZÁLEZ M, GALEGO N, ORTIZ DEL TORO P, RAPADO M. Radiation induced graft copolymerization of vinyl acetate onto poly (3-hydroxybutyrate). Paper summitted to JPSCH. 2008.

[20] GRUSHEVSKAYA LN, ALIYEV RE, KABANOV VY. Radiation induced graft copolymerization of acrylamide onto polyethylene. Polymer Science U.S.S.R. 1989; 31(7): 1530-1534.

Recibido: 25 de febrero de 2008.

Aceptado: 26 de marzo de 2008.

mikegcu@gmail.com, rapado@ceaden.edu.cu